Tungsten

The history of welding metals together is very old with the most primitive examples from the Bronze Age and the Iron Age in Europe and the Middle East counties. Welding is a creative skill that has a lot of scope.

A few sources of welding energy are a gas flame, an electric arc, a laser, an electron beam, friction, and ultrasound. Despite the fact that, welding can be done in many dissimilar situations, like open air, under water and in outer space welding in industries is of great use and is most often in almost all industrial processes.

Even today, as technology and safety gears are advancing, welding continues to be a potentially dangerous process. Welders need to take safety measures to avoid burns, electric shock, eye damage, poisonous fumes, and overexposure to ultraviolet light and radiation.

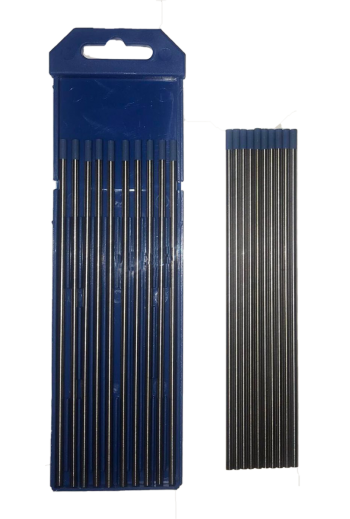

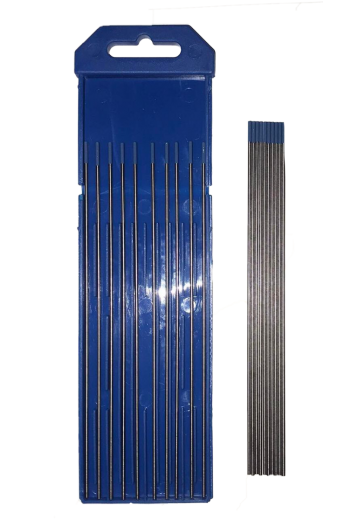

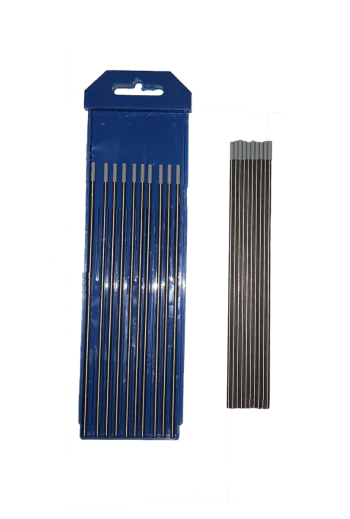

Tungsten is one of the most common metal elements used in the manufacturing industry of TIG electrodes. These electrodes are mainly used due to their hardness and high temperature resistance. Likewise, Tungsten has a very high melting point and therefore more practical in welding processes.

Good arc stability for AC welding with balanced wave is provided by these electrodes when heated and AC sine wave with good arc stability is produced when tungsten is used for welding aluminum and magnesium specifically. Welding performance and arc quality mainly depends on the type and shape of tungsten that is been used.